Press vs. Solder: Why Press Fittings Are the Future of Plumbing and Heating Installations

For decades, soldering has been the go-to method for connecting copper pipes in plumbing and heating systems. But times are changing. Installers, contractors, and even merchants are now turning to modern press fitting technology as a faster, safer, and more reliable alternative. With growing demand for efficiency and compliance, press fittings are quickly becoming the future of the industry and PRESS-TITE is leading the way.

The Traditional Method: Soldering

Soldering copper joints has long been trusted for its strength and familiarity. By heating the joint and applying flux and solder, a secure connection is formed that can last for decades. However, soldering comes with challenges. The process requires open flames, hot-work permits, and skilled labour. It can be time-consuming on large projects, and working in tight spaces or near combustible materials increases both difficulty and risk. While soldering will always have its place, today’s projects demand solutions that reduce installation time without compromising reliability.

The Modern Alternative: Press Fittings

Press fittings use mechanical force from a press tool to form a permanent, leak-free connection. Instead of flux and flames, an M-profile fitting is pressed securely onto the pipe, creating a consistent joint in seconds.

The advantages are clear:

- Speed: Installations are up to 50% faster than soldering.

- Safety: No flames, no hot-work permits, and no risk of fire.

- Reliability: Every press creates a uniform joint, reducing call-backs, with the use of PIR (press indicator ring)

- Convenience: Fittings can be installed in tight spaces and even on wet pipes.

This combination of speed, safety, and consistency is why many installers are making press their default method.

Press vs. Solder: Key Advantages

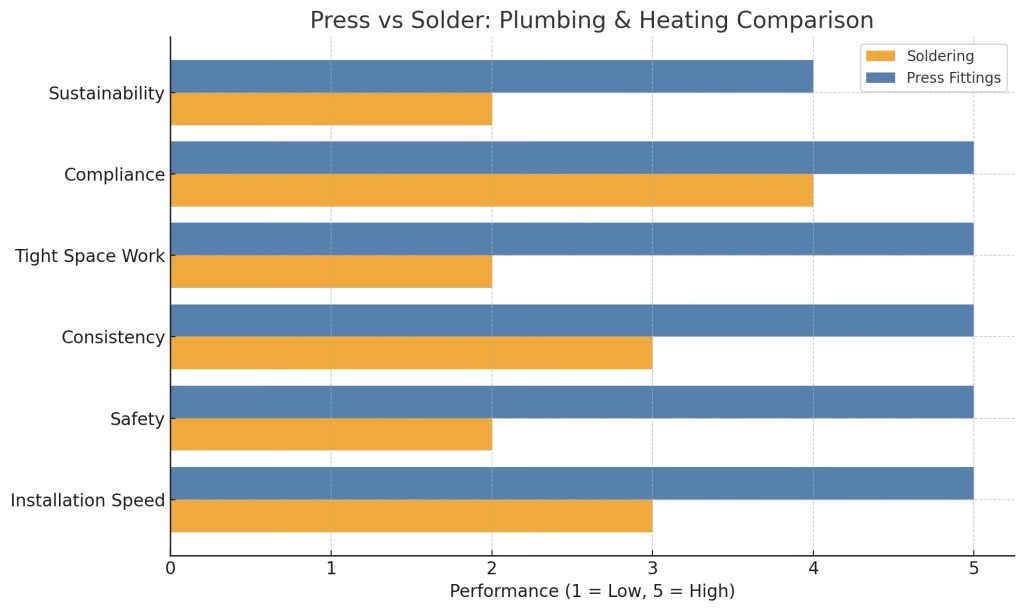

Table 1 – Press vs Solder Comparison Chart

When comparing press fittings to soldering, the benefits quickly stand out:

- Faster installation: Save valuable labour time, especially on large-scale projects.

- Improved safety: Eliminate the risks of open flames and fire hazards.

- Greater consistency: Reduce variability from operator skill and achieve reliable joints every time.

- Work flexibility: Install fittings in confined spaces or damp environments where soldering is impractical.

- Regulatory compliance: WRAS and gas approvals ensure peace of mind for water and heating applications.

- Sustainability: Press technology reduces the need for flux, gas canisters, and consumables making it a cleaner, more efficient choice.

These benefits have been translated into a quick view comparison chart ( See Table 1)

Applications Across the Industry

Press-Tite fittings are designed to give installers and merchants complete confidence. The range includes:

- Full WRAS and gas approvals for maximum compliance.

- Comprehensive M-profile fittings and valves to cover every application.

- Trusted supply chain — backed by a leading independent wholesaler with 30 years of reputation in copper plumbing solutions.

With Press-Tite, you get a solution that combines performance, reliability, and peace of mind helping you deliver every project on time and to the highest standard.

Conclusion

Soldering has served the industry well, but the future belongs to press. Faster, safer, and more consistent, press fittings are transforming plumbing and heating installations. For installers and merchants who want to stay ahead, Press-Tite offers a proven, approved, and trusted solution.

Discover the full Press-Tite range today and see why more professionals are making the switch.